Services

common services

These are some of the common services offered in the diving industry. Our company provides comprehensive solutions across commercial diving, underwater inspections, environmental services, and recreational diving, ensuring we meet the diverse requirements of our clients.

Preparation and Installation of Diving Equipment

Before commencing industry diving operations, it is essential to prepare and install all diving equivalents, such as communication systems, safety gear, and breathing apparatus, to ensure the safety and efficiency of the underwater activities.

Structural Inspection of Gas and Oil Pipelines

Checking Structure for Gas and Oil Lines involves inspecting the physical condition and integrity of pipelines and related infrastructure to ensure they meet safety, regulatory, and operational standards. This process includes detecting corrosion, checking for leaks, verifying weld quality, and ensuring that the structural components can withstand operational pressures. Regular checks help prevent failures, ensure environmental safety, and maintain the reliability of the gas and oil distribution network.

Oil and Gas Monitoring

Oil and Gas Inspection involves the systematic evaluation and monitoring of equipment, pipelines, wells, and facilities within the oil and gas industry. It ensures safety, compliance with regulations, and optimal functioning of systems to prevent leaks, equipment failure, and environmental hazards. Regular inspections help maintain operational efficiency and uphold industry standards.

inspection and Maintenance of Diving Equipment for Subsea Operations

Inspection and Maintenance of Diving Equipment for Subsea Operations involves systematic evaluations of diving gear to ensure safety, reliability, and compliance with industry standards. This process includes checking the integrity of helmets, suits, communication devices, and breathing apparatus, as well as testing functionality and identifying any necessary repairs. Regular maintenance is crucial to prevent equipment failure during underwater operations, ensuring the safety of divers and the success of subsea tasks in challenging environments such as oil and gas exploration.

Emergency Response and Rescue Services

OUR SERVICES

Salvage

Marine Salvage and Wreck Recovery involves the process of locating, securing, retrieving, and restoring vessels, cargo, or valuable materials lost or damaged at sea due to accidents, sinking, or storms. This specialized branch of commercial diving focuses on minimizing environmental hazards, recovering valuable assets, and ensuring the safety of marine operations.

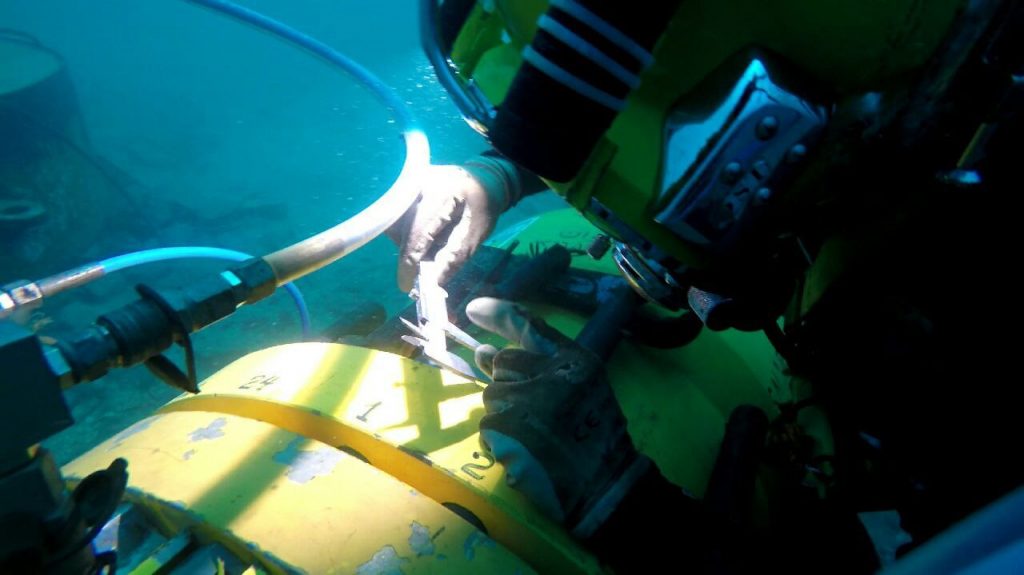

SPM diving support

SPM (Single Point Mooring) Diving Support refers to specialized diving services that assist in the inspection, maintenance, and repair of Single Point Mooring systems. These systems are offshore floating platforms that allow tankers to load or unload cargo (typically oil or gas) without having to dock at a harbor. The SPM is connected to the seabed via anchors and pipelines, making it essential to keep the system in good working order.

Anode replacement

`Anode replacement is a critical underwater maintenance task performed to protect metal structures, such as ships’ hulls, offshore platforms, pipelines, and subsea equipment, from corrosion. This is part of a system called cathodic protection, where sacrificial anodes, made of metals like zinc, aluminum, or magnesium, are installed on submerged metallic surfaces.`

Pipeline IRM

Pipeline IRM (Inspection, Repair, and Maintenance) refers to the regular and systematic process of inspecting, repairing, and maintaining subsea pipelines that transport oil, gas, or other fluids. These pipelines are critical for offshore and underwater operations, making IRM services essential to ensure their safety, integrity, and uninterrupted operation.

SPM Installation

SPM (Single Point Mooring) Installation involves setting up a floating offshore mooring system used for the transfer of fluids between tankers and pipelines. The process is complex and typically conducted in deep water, requiring careful planning, specialized equipment, and adherence to safety and environmental standards.

Fixing and Blocking of Hatches in a Dam

Fixing and Blocking of Hatches in a Dam are critical procedures to control water flow, ensure structural integrity, and facilitate maintenance or repairs. Hatches in dams are typically used to control the release of water from reservoirs, manage water levels, or allow access to internal structures for inspection.

Welding and Cutting Underwater Bases

Welding and Cutting Underwater Bases involves performing metal welding and cutting tasks in underwater environments, typically in offshore industries, shipbuilding, and underwater construction projects like bridges, pipelines, or oil rigs. Specialized techniques and equipment are used to ensure the structural integrity and safety of operations in high-pressure and often low-visibility conditions.

High Cleaning of Large and Small Floats

High Cleaning of Large and Small Floats (Buoys) refers to the process of removing marine growth, debris, and other contaminants from the surface of floating structures used in marine environments. Floats or buoys are vital for navigation, mooring systems (like SPMs), and structural stability in offshore platforms, and regular cleaning is essential to maintain their functionality and longevity.

Bedding

Bedding (or Baging) Under Oil and Gas Pipelines refers to the process of providing support and protection to pipelines during installation, particularly in trenching operations. This is crucial to ensure the pipeline’s stability, prevent mechanical damage, and maintain the integrity of the pipeline over time, especially in challenging terrains like offshore environments or soft soils.

Welding and Cutting Underwater Bases

Welding and Cutting Underwater Bases involves performing metal welding and cutting tasks in underwater environments, typically in offshore industries, shipbuilding, and underwater construction projects like bridges, pipelines, or oil rigs. Specialized techniques and equipment are used to ensure the structural integrity and safety of operations in high-pressure and often low-visibility conditions.

High Cleaning of Large and Small Floats

High Cleaning of Large and Small Floats (Buoys) refers to the process of removing marine growth, debris, and other contaminants from the surface of floating structures used in marine environments. Floats or buoys are vital for navigation, mooring systems (like SPMs), and structural stability in offshore platforms, and regular cleaning is essential to maintain their functionality and longevity.

Install and replace sacricial in gas and oil pltafrom

Replacing sacrificial anodes on gas and oil platforms is essential to prevent corrosion on submerged metal structures, such as legs, risers, pipelines, and other critical components. The process can be complex due to the challenging offshore environment but follows standard procedures similar to onshore anode replacement, with additional safety and logistical considerations.